![]()

The perimeter wall of the mold is constructed of 2-piece plywood panels. The outer panels lock together with carraiage bolt pins through 2x4 bars at each end. 2X4 spacers separate the outer and inner panels. The walls are braced from behind by the earth wall of the containing pit. They would otherwise not withstand the outward pressure of the contained liquid.

The panels are in 2 pieces to facilitate the separate casting step of the normal density concrete outer shell. First the cellular concrete inner honeycomb structure is cast and allowed to set. Then the inner panels are pulled up and away, leaving 4” more space for the shell to be cast.

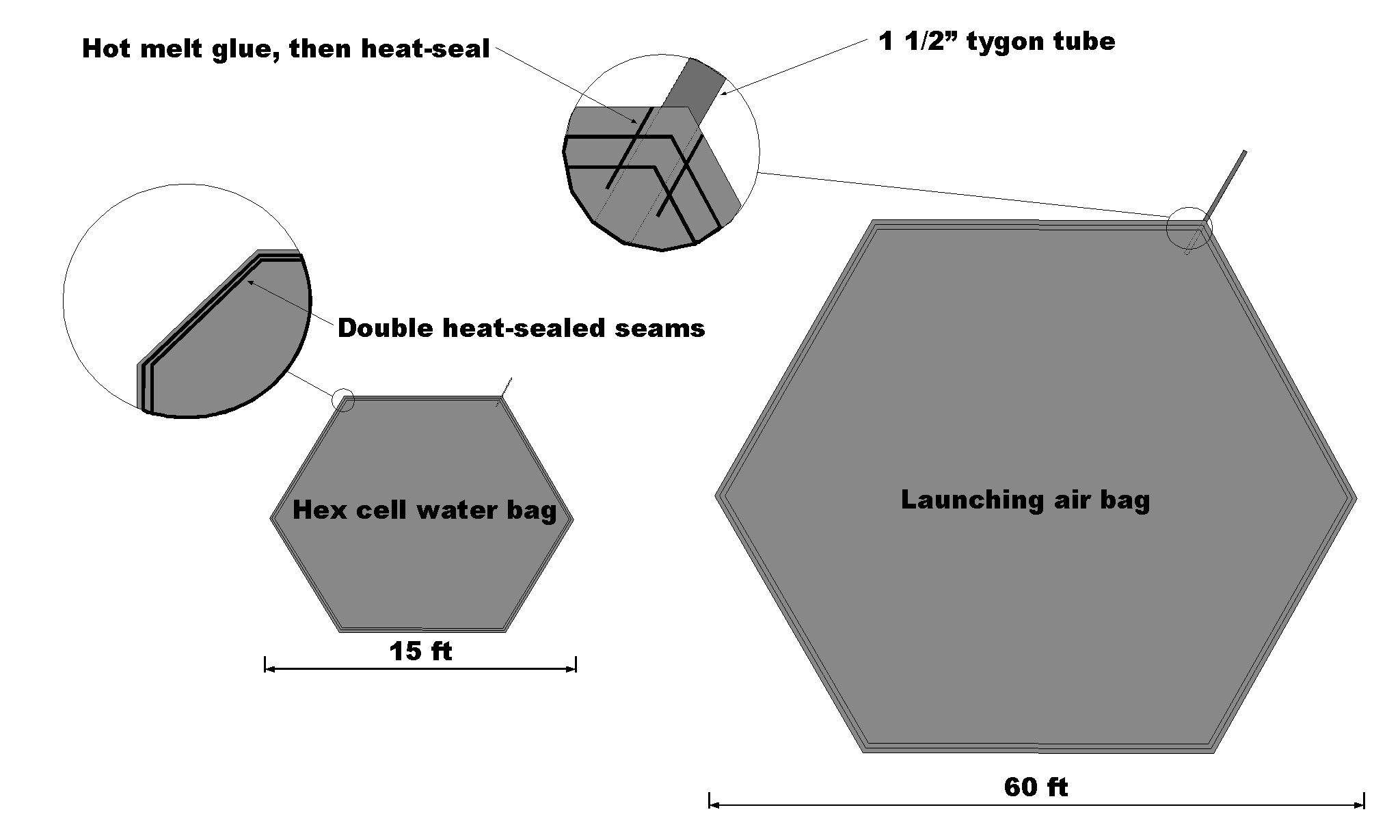

Large plastic bags are used to contain water to form the interior hex cells by displacing concrete, and to pneumaticly lift the 115 ton module and launch it. The bags are constructed from pairs of 6 mil poly sheets, heat-sealed together.